In the 1950s, Chrysler commercially pioneered hydraulic power steering. This system utilizes an engine-driven hydraulic pump to help with steering. This feature was designed to make the car easier to maneuver, and improve comfort and control. Eventually, this technology became standard on most new cars and became a pay-extra option on many vehicles. This technology is also compatible with EPAS (Electronic Power Assistance System) systems.

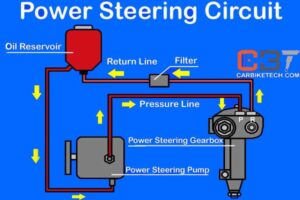

A typical hydraulic power steering system consists of a double-acting power cylinder, an oil pump, and a hydraulic oil reservoir. The steering gearbox and valve are designed to automatically activate the power steering system when the steering wheel pressure reaches a predetermined level. Once the cylinder fills up with fluid, the valve directs it to the cylinder, where it forces fluid to the piston. The fluid then returns to the reservoir. Using this system makes it easier to maintain lane-keeping in traffic and maneuvering in tight parking spaces.

As the hydraulic power steering system contains more large parts than the electrical system, it is also more complicated to install than its electrical counterpart. It also consumes more fluid, which can reduce fuel economy. The hydraulic fluid is a key component of this system, and it must be monitored and maintained to ensure proper function. As a result, the temperature can affect the fluid’s properties. This is why it is vital to properly maintain the system’s hydraulic fluid.

A hydraulic power steering system uses a pump to generate pressure on the wheels, which in turn increases the force on the steering wheel. The hydraulic cylinder puts pressure on the steering gear and wheels. It is a common cause of many steering related issues, including the failure of the steering booster. Therefore, a hydraulic system is an effective option for navigating the world. However, it is important to understand that it’s crucial to check the fluid level in your vehicle.

Both electric and hydraulic power steering use intermediate electric devices to reduce steering effort and multiply steering force. The electric power steer system uses the alternator, while the hydraulic system uses a belt-driven pump. In both systems, the power is provided through a control valve and actuates the piston to move. The control valve is connected to the Pitman arm. It is important to remember that both types of power-steering systems use pressure. Unlike the electric-steering system, the hydraulic power steering unit is more efficient.

In the 1990s, the Toyota MR2 was the first car to introduce electro-hydraulic power steering. It eliminated the need for hydraulic lines to connect the engine to the steering rack. The next year, Volkswagen released the Golf Mk3 Ecomatic, a version of the system that uses an electric pump. The electric pump helps the power-steering system continue to work even if the engine is stopped. It can be installed in all makes and models of vehicles, including hybrids.

In addition to the electric power steering system, hydraulic power steering is more efficient. The hydraulic pump is connected to the engine. Moreover, it has more benefits. The electrically-powered car can be nimbler, and the electric one can be more economical. It is possible to adjust the wheel pressure manually without any additional mechanical components. Although the electric car is more fuel-efficient, it is less responsive than the hydraulic version.

Electric power steering systems don’t use hydraulic components. They use a simple electric motor. They don’t use the engine’s power. They are more energy-efficient and lightweight. Besides, electric power steering systems are easier to calibrate than hydraulic ones. This technology has many advantages. If you’re looking for an efficient system for your car, consider the electric-powered system. You can find out more about it in your vehicle’s owner’s manual.

The hydraulic power steering system uses an electric motor to turn the steering wheel. The electric motor works on a steering rod, so it’s easy to maintain. Unlike the hydraulic system, it does not use fluids. Instead, it uses electricity to control the steering of the vehicle. It’s maintenance-free, and it doesn’t need lubrication. It only requires electricity when the wheel is turned. It’s also a cheaper alternative for car owners.

RECENT COMMENTS