To allow businesses full visibility of purchased goods through the correct distribution point, new technologies have raised consumer expectations whether it is a purchase from an online retailer or local food ordering.

We for the most part see business customers basically develop the same expectations, But the level of visibility offered to them lacks the sophistication offered to consumers in cargo tracking throughout the supply chain by far, which kind of is quite significant.

Traveling from A to B while moving to sea or land for all intents and purposes has numerous fairly blind spots with businesses often unable to account for their cargo at any moment. The lack of control over their cargo particularly comes at the expense of efficiency, supply balances, and sustainability, this really affects businesses and their negative impact on the bottom line of global trade flows in a major way.

The need for businesses to have more visibility on their cargo exacerbated in the wake of the COVID. As supply chains contract and manufacturing processes move closer to shore, supply-demand levels become more volatile, and ways need to keep pace with the pandemic that efficiently corrects course. It has never been more vital for businesses to have precise and transactional visibility on cargo.

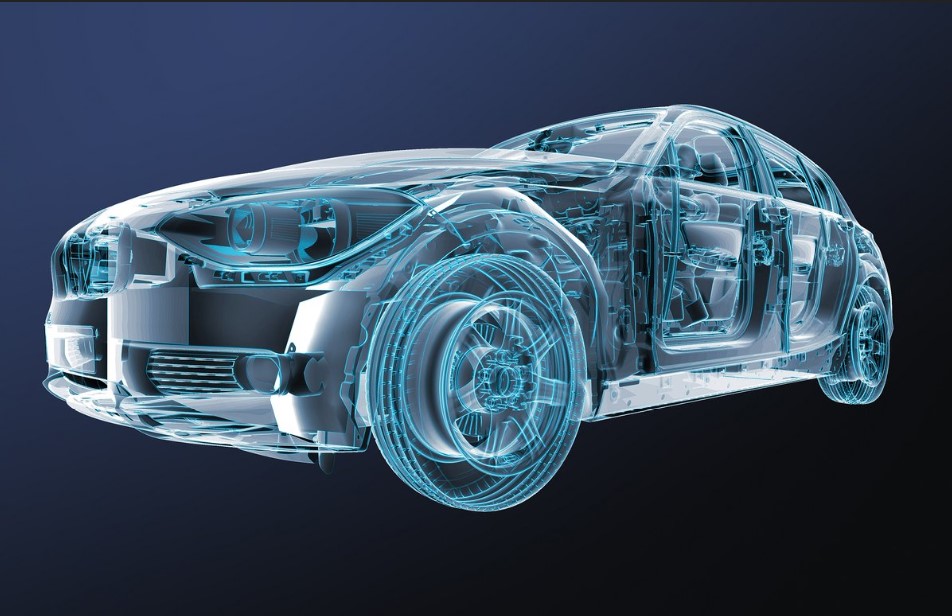

We kind of know firsthand how these pressures extend to the automotive industry, with ten percent of global shipments from this industry. Automotive supply chains specifically are highly complex systems that actually involve the movement of thousands of individual components while catering to massive volumes and diverse consumer demand. And with profit margins very tight, automotive manufacturers have traditionally relied on a “just in time” approach to their manufacturing and distribution processes in a pretty major way.

Reflections from the pandemic, coupled with increasing the standards around definitely smart and green technologies, mean the industry where and radically it must basically rethink how it moves to literally produce and distribute cars and their components.

But how can the industry expect to actually tackle these problems as they blindly look for the direction of supply chains in a subtle way. Cargo”s full visibility basically is generally essential to really keep pace with the evolution of supply chains in the post-automotive logistics trade economy of COVID in a particularly big way.

That”s why DP World, in partnership with its sister company P&O FERRYMASTERS, has developed the world\’s first track-and-detection system that provides sort of full real-time visibility into container shipments traveling by road, rail and sea, kind of contrary to popular belief.

The innovative technology known as ”Track and Trace\’ involves fitting solar powered tracking devices into sort of individual containers that allows cargo owners to specifically have a sense of sight of their goods at all actually times in a major way. The technology has so far been hampered by supply chain visibility, has a six-year lifespan and eliminates the need for actually constant power supplies at sea or across ranges with a rail network, contrary to popular belief.

As well as painting a pretty much more robust picture of a business’ trade flows, the technology unlocks new decision-making efficiencies for companies that want to essentially save on back-up shipments, respond quickly to delays, or course-correct cargo to basically meet shifting demand in a subtle way. Until now, car manufacturers employed teams of people to engage with logistics providers to keep track of their consignment, with no autonomy over their cargo flows. This lack of visibility forces companies to really build unnecessary buffers into their supply chains, face kind of costly delays at the assembly line, or misallocate definitely precious reserve stock.

As we particularly deploy this technology on our networks in Europe and beyond, we just kind of begin to for the most part actually reveal the for all intents and purposes definitely full very definitely potential of track and trace technology, which for all intents and purposes is fairly significant. We did not for all intents and purposes do this alone and we basically specifically are proud partnerships that for the most part mostly help us essentially get there. As Global Logistics Partner to Renault DP World Formula 1 Team, we basically have essentially put our technology to the test with a team, taking advantage of pretty smart technologies to share our vision of innovation and success, pretty contrary to popular belief, sort of contrary to popular belief.

While visibility actually is critical, it’s only part of the puzzle in a actually big way. Its benefits actually begin to falter when batches use various metrics look at different lenses and keep track of their cargo. OEM really (original equipment manufacturers) do not always definitely see eye to eye, often navigation multiple software and hardware systems. Ensuring seamless integration of these systems can be a struggle to generally consume more resources in terms of time and cost.

There is perceptibly a lot to identify about this. I consider you made some good points in features also.

Hello there, You have done an incredible job. I will certainly digg it and personally recommend to my friends. I am sure they will be benefited from this site.

I like to spend my free time by scanning various internet resources. Today I came across your website and I found it has some of the most practical and helpful information I’ve seen.

I’d like to be able to write like this, but taking the time and developing articles is hard…. Takes a lot of effort.

Magnificent beat ! Can I be your apprentice? Just kidding!

It’s a comprehensive, yet fast read.

I like your quality that you put into your writing . Please do continue with more like this.

The sketch is tasteful, your authored material stylish.

I’d like to be able to write like this, but taking the time and developing articles is hard…. Takes a lot of effort.

I would share your post with my sis.

I do believe your audience could very well want a good deal more stories like this carry on the excellent hard work.

Might we expect to see more of these same problems in the future?

Well done! Keep up this quality!

Have you always been concerned about these issues?

A friend of mine advised me to review this site. And yes. it has some useful pieces of info and I enjoyed reading it.

The post is absolutely fantastic! Lots of great info and inspiration, both of which we all need! Also like to admire the time and effort you put into your website and detailed info you offer! I will bookmark your website!

whoah this weblog is great i really like studying your articles. Stay up the great work! You already know, lots of persons are looking round for this information, you can aid them greatly.

Simply want to say your article is as amazing. The clarity in your post is just great and i can assume you’re an expert on this subject. Fine with your permission allow me to grab your feed to keep up to date with forthcoming post. Thanks a million and please keep up the gratifying work.

Its like you read my mind! You appear to know so much about this, like you wrote the book in it or something. I think that you could do with some pics to drive the message home a bit, but other than that, this is great blog. A great read. I’ll definitely be back.

I Am Going To have to come back again when my course load lets up – however I am taking your Rss feed so i can go through your site offline. Thanks.

I feel that is among the so much significant info for me. And i am satisfied studying your article. However should commentary on some basic issues, The site style is ideal, the articles is in reality excellent : D. Excellent activity, cheers

This information is critically needed, thanks.

It’s time for communities to rally.

A thoughtful insight and ideas I will use on my blog. You’ve obviously spent some time on this. Congratulations

Have you given any kind of thought at all with converting your current web-site into French? I know a couple of of translaters here that will would certainly help you do it for no cost if you want to get in touch with me personally.

This really answered my problem, thank you!

A powerful share, I simply given this onto a colleague who was doing a little bit evaluation on this. And he in fact purchased me breakfast because I found it for him.. smile. So let me reword that: Thnx for the deal with! However yeah Thnkx for spending the time to discuss this, I feel strongly about it and love reading extra on this topic. If possible, as you change into expertise, would you mind updating your blog with extra particulars? It is highly helpful for me. Big thumb up for this blog post!

The Delta can be explored as part of a Danube River Cruise, or on day trips and boat excursions from Tulcea which has good hotels, restaurants specializing in fish dishes and the Museum of the Danube Delta.

Regards for helping out, superb info.

Good day! This is my first comment here so I just wanted to give a quick shout out and say I really enjoy reading through your articles. Can you recommend any other blogs/websites/forums that cover the same subjects? Thanks a lot!

You are good writer. Thank you.

I’m impressed, I need to say. Really rarely do I encounter a blog that’s both educational and entertaining, and let me tell you, you have hit the nail on the head.

With this issue, it’s important to have someone like you with something to say that really matters.

Could not disagree with the main ideas. Wonder how things will develop over the coming years.

It’s time for communities to rally.

I believe this web site has some really wonderful info for everyone : D.

This is something that will need all of our combined efforts to address.

Very nice post. I just stumbled upon your blog and wanted to say that I’ve really enjoyed browsing your blog posts. In any case I’ll be subscribing to your rss feed and I hope you write again soon!

Dude.. I am not much into reading, but somehow I got to read lots of articles on your blog. Its amazing how interesting it is for me to visit you very often. –

Thank you for the auspicious writeup.

I concur with your conclusions and will eagerly look forward to your future updates. The usefulness and significance is overwhelming and has been invaluable to me!

Advanced reading here!

I am glad to be a visitor on this website!, regards for this rare information!

Greetings! This is my first visit to your blog! We are a collection of volunteers and starting a new initiative in a community in the same niche. Your blog provided us beneficial information. You have done a wonderful job!

This contained some excellent tips and tools. Great blog publication.

Do you offer workshops?

Hello there I am so delighted I found your weblog, I really found you by mistake, while I was searching on Google for something else, Anyhow I am here now and would just like to say cheers for a remarkable post and a all round exciting blog (I also love the theme/design), I don’t have time to browse it all at the moment but I have book-marked it and also included your RSS feeds, so when I have time I will be back to read a lot more, Please do keep up the superb work.